YG nitrile gloves making machine adopts the current more advanced glove production technology layout and production technology, and the product qualification rate reaches more than 98%, adopts the continuous production method and direct dipping method, uniform film formation, bright color, various models, and specifications. The nitrile gloves machine's length is 50 meters, 60 meters, and 80 Various specificationssuch as 100 meters, the high degree of automation, large output, and configurable automatic demoulding.

| model | Production capacity pcs / H | Machine size-L*W*H/ meters | Factory size-L*W*H/ meters | Heating consumption m³/h | Power / Kw | Mold QTY | Chain length M |

|

YG-NBR 30 X1 |

45000 |

30 * 5 * 8 M |

40 * 6 * 9 M |

55 |

60 |

2520 |

252 |

|

YG-NBR 55 X1 |

110000 |

60 * 5 *6 M |

60 * 6 *7.5 M |

110 |

120 |

4000 |

400 |

|

YG-NBR 70 X1 |

220000 |

70 * 5 * 7.2 M |

80 * 6 *7.5 M |

130 |

120 |

6800 |

680 |

|

YG-NBR 112X1 |

280000 |

112 * 5 * 6.5 M |

122 * 6 * 7 M |

150 |

130 |

7800 |

780 |

|

YG-NBR 190 X2 |

550000 |

150 *4.5 * 10 M |

160 * 6 * 11 M |

280 |

250 |

24000 |

1200 |

|

YG-NBR 220 X2 |

1000000 |

190 * 4.5 * 10 M |

195 * 6 * 11 M |

330 |

275 |

28200 |

1410 |

|

YG-Latex- 100x1 |

1200000 |

220 * 4.5 * 11 M |

240 * 6 * 12 M |

400 |

300 |

29000 |

1450 |

| YG-SBB110*6 |

300000 |

100 * 5 * 6.5 M |

110 * 6 * 7 M |

140 |

120 |

8000 |

800 |

|

YG-PVC-130x2 |

1000000 |

130 * 5 * 7.5 M |

140 * 6 * 8.5 M |

200 |

180 |

18000 |

900 |

Note: models with different lengths, heights, and costs can be designed

Note: models with different lengths, heights, and costs can be designed

1. Using the most advanced glove production technology layout and production technology, the product qualification rate is over 98%;

2. With the introduction of foreign advanced transmission main chain structure, the chain running resistance is small, and the production runs smoothly at high speed;

3. TPU coating technology;

4. Imported surface active agent coagulant, film formation is more uniform, and powder-free demoulding;

5. The main motor is dragged, which solves the problems of multiple dragging, difficult synchronization, multiple failure points, and difficult maintenance;

6. Vertical hot air circulation is used in the drying oven, which saves energy consumption by nearly 20% compared with other forms of hot air circulation;

7. Mold orientation and on-machine coding technology;

8. Six-roller long-hair brushing technology for mold finger cleaning;

9. Multiple specifications are produced on the same machine, curling is automatically adjusted, PU curling roller, long service life;

10. Models with different lengths, heights, and costs can be designed according to customer needs.

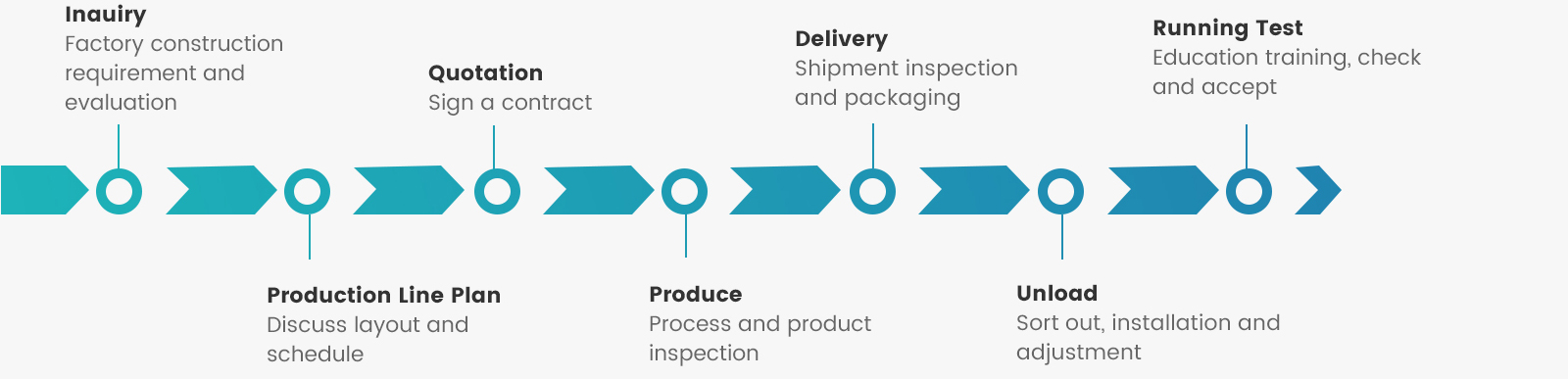

Yugong machinery is a professional manufacturer of disposable gloves making machine. We provide free design, quotation, manufacturing, installation, start-up production and all-round services, and provide turnkey engineering solutions according to different customer requirements.

Contact Now +

Contact Now +

Do you need to build a new glove production line? Just need to replace the old machine? Do you need glove packing machine? Glove Dipping Machine? Or another machine? Contact us for professional solutions, free quotes, and high-quality equipment.

Yugong customizes diversified glove production lines for global customers, and has more than 300 successful cases of glove line factories around the world. We provide one-to-one service for each glove line customer, regularly return to regular customer customers, and help customers solve equipment and technical problems.